The Randi Group method

Production processes

Randi Group products, all totally natural, are extracted from residues and by-products of the

wine industry from which the main products destined for the food, wine, cosmetics and

pharmaceutical industries are made.

What is the Randi method?

At Randi, production combines the most ancient manufacturing processes with latest generation techniques, ensuring the best standards in terms of quality and quantity. A quest for excellence, always from a sustainable viewpoint, with a growing commitment to the self-production of electrical and thermal energy, using the same materials from which the finished products are obtained .

Randi Group has, in fact, devised a self-monitoring system that involves the production processes at its plants: a systematic method that evaluates all aspects, be they managerial or operational. From safety to food hygiene, from materials to the end product, each phase is monitored and guaranteed, ensuring a supply that always complies with the strictest legal indications and the specific requests of our customers.

What are the raw materials used?

There are three raw materials originating from the wine industry that are used to make tartaric (and other) products. Marc, lees and crude bitartrates.

Marc

Features

This is the solid and semi-solid part of the grapes left over after crushing, made up of grape seeds, stems (the woody part) and skins. The pomace contains potassium bitartrate and ethyl alcohol. The quality of the pomace depends on the type of grape, the maturation and the winemaking system.

Uses

Pomace is used in the production of ethyl alcohol, grape seed oil, calcium tartrate and grape seed pellets. The residual product, known as exhausted pomace, is used to produce thermal and electrical energy.

Processing

The marc is washed in hot water and the alcoholic liquid obtained is sent to the distillation plant, where it is concentrated to around 96% alcohol. This product is marketed as a raw alcohol for industrial use, or it can undergo a second distillation and “purification” phase and be transformed into food-grade alcohol. During the distillation process, the alcoholic liquid is separated from its tartaric component, which is sent to the calcium tartrate production plant and later to the tartaric acid production plant.

The exhausted marc, stripped of its alcoholic and tartaric components, on the other hand, is screened and sieved to extract the seeds. The discarded material is used in the biomass cogeneration plant to produce thermal and electrical energy from renewable sources.

The grape seeds are then dried and pressed to extract crude oil. The waste material from this process is used in turn as fuel in the cogeneration plant and for the production of grape seed pellets.

The crude oil is then sent to the refining plant where, by means of exclusively physical and mechanical processes, it is transformed into grape seed oil.

Lees

Features

Lees are a by-product of the filtration and concentration of the must. Depending on the process used by the winery, they may be liquid or solid, cream or red in colour depending on the type of grape.

Uses

Production of calcium tartrate and ethyl alcohol.

Processing

The raw material is prepared and sent to the distillation plant, where food-grade alcohol, spirit or raw alcohol for industrial use are produced. During the distillation process, the alcoholic component is separated from the tartaric component, which is sent to the calcium tartrate production plant and later to the tartaric acid production plant. In these phases, the materials coming from the processing of the lees follow the same path as those coming from the processing of the pomace, and the waste materials are sent to the biodigestion plants where a biogas is produced, used in a separate cogeneration plant to produce electrical energy from renewable sources. The digested material is then purified and reused as a fertiliser.

Barrel tartar, or raw tartar

Features

The crude bitartrates are divided into raw tartrate and crude bitartrate from concentration. Raw tartrate is the residue that settles in the storage tanks after the wine has been decanted, and crude bitartrate from concentration is the residue that settles after the concentration of the must. Both are very rich in the tartaric component, which makes them particularly valuable.

Uses

Production of cream of tartar, neutral potassium tartrate and sodium potassium tartrate.

Processing

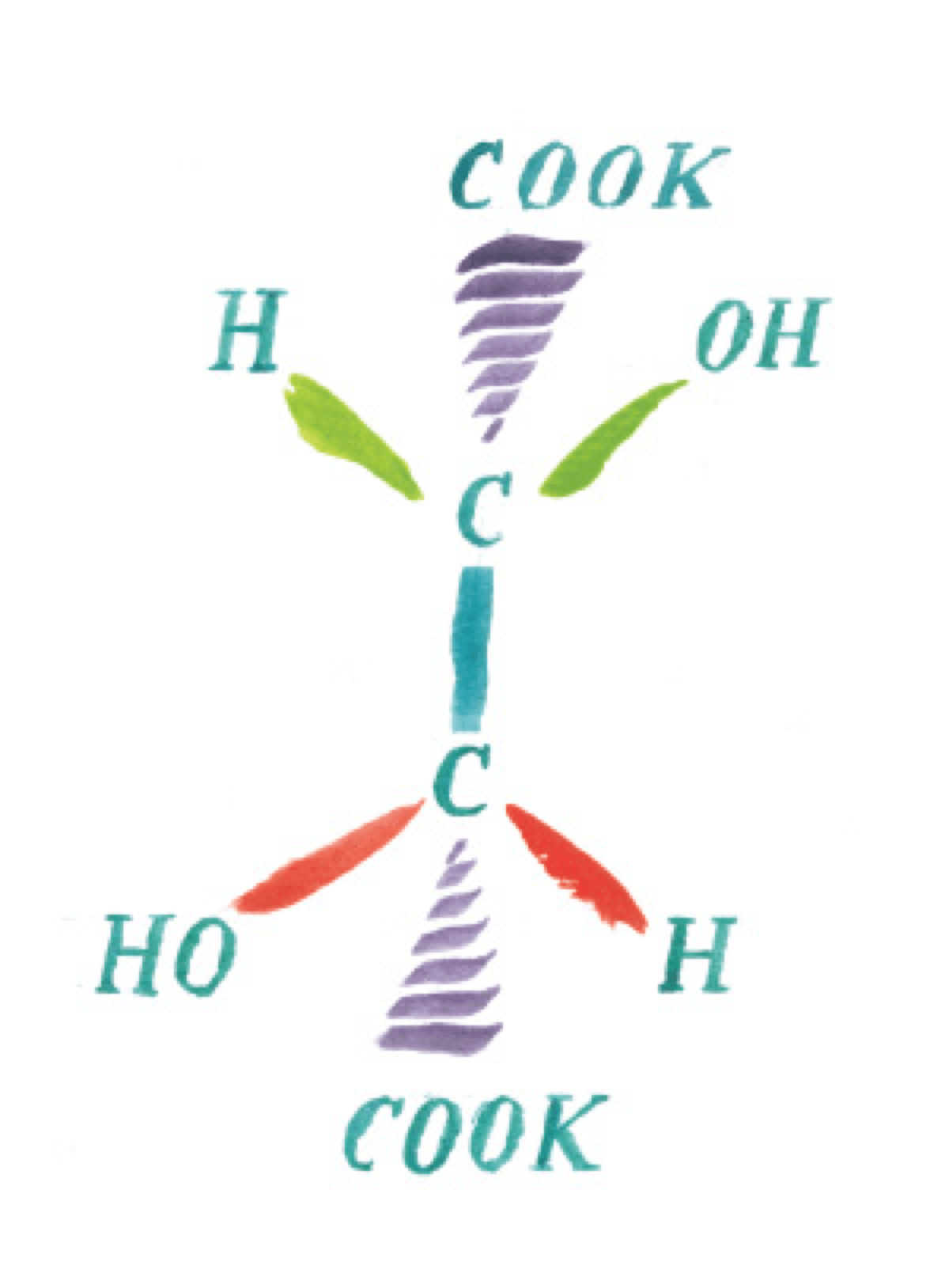

The cream of tartar is extracted directly from the raw tartrate and subsequently used as a raw material for the production of neutral potassium tartrate and sodium potassium tartrate (Rochelle salt).

"Of business it is encouraging thought"

"Of business it is encouraging thought"